Acoustic Horn - A Smart Cleaning Method!

Installing an Acoustic Horn inside boilers limits the number of paths needed for retractable soot blowers and gives the all-around cleaning of the boiler. The acoustic horn uses acoustic or sound waves of extremely diffractive low frequency to be able to clean all surface areas in any orientation. The use of low frequency indicates that rather than just pushing a gas channel to maintain differential pressure throughout the boiler, acoustic horns clean all the heat exchange surfaces while simultaneously preserving thermal efficiency and differential pressure. Innovative Enerpro Pvt. Ltd. acoustic horns can operate at the lowest of the frequencies to deliver better cleaning experiences. Our products have better efficiency and thus offer better performance. No wonder why we are the leading Acoustic Horn manufacturers In India.

Make a call

+91 98 241 5754

Email us

info@ienerpro.com

Acoustic Horn - We Thrive With Technology!

At one time, acoustic horns or cleaners were considered the last resort against the challenging ash build-up issues. Since its inception more than a decade ago, the technology has shown to be successful in a wide range of applications. In addition, the equipment gets considered the first choice for cleaning procedures that saves money, increases efficiency, and minimises damaging vital components. Innovative Enerpro Pvt. Ltd. has been in the business of energy products for more than a decade now. We thoroughly comprehend the applications of an acoustic horn. To withstand all such demands and needs we supply high-grade acoustic horns that provide value returns to our clients. Such an approach has made us the leading Acoustic Horn Suppliers in various local and international markets.

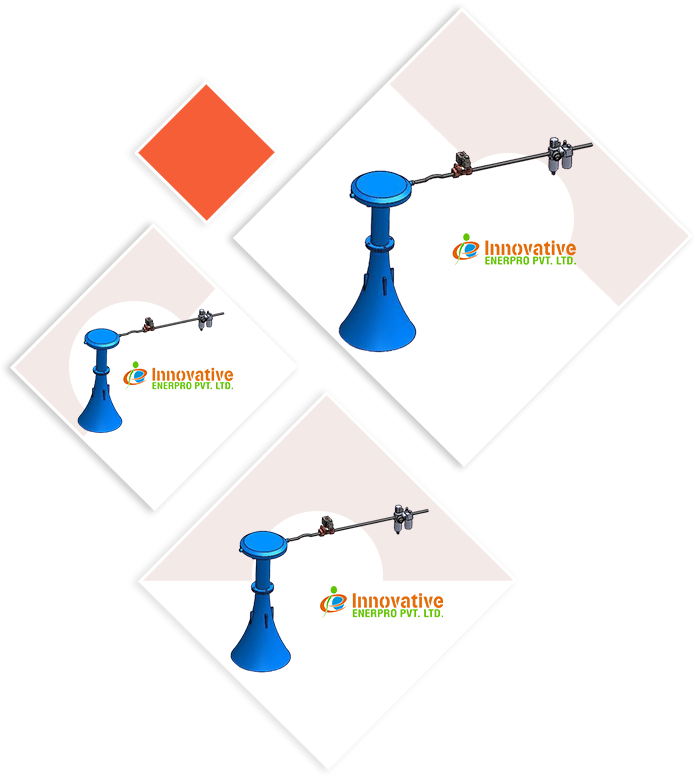

Product Gallery

Further Product Detail

- Purchase and installation of the acoustic horn are less expensive.

- Unlike other methods, they do not utilise high-pressure steam or water and hence offer zero corrosion.

- They are environmentally benign.

- Simple to keep clean and maintain.

- The most cost-effective cleaning solution at an inaccessible location

- A high level of efficiency across the various zones of the boiler

- Eliminates the issues of ratholing and bridging in the silo

- Reduce the amount of air that gets consumed and lengthen the life of the bag filter

- A controller based on a microprocessor can programme the preferred cleaning frequency, which ensures that the heat transfer area is always clean.

- A diverse temperature range, all the way up to 1250 degrees Celsius.

- Performs with applications having high corrosion risk with ease.