Condensate Recovery System - The Working Principle

A condensate recovery system moves steam condensate from the plant to the boiler feedwater tank using steam or air as the energy source. There are two stages at which the pump works, the filling stage and the pumping stage. In filling mode, condensate from the process gets collected in the pump receiver tank. Valves start filling the pumping tank while the motive inlet stays closed, and the vent outlet is open to avoid back pressure. It increases the levels from low to high. While in pumping mode, the vent valve closes, and the motive steam or air valve activates when the level reaches the predetermined high level. It will let steam enter the tank, which will cause the water level to drop. The intake check valve will be closed, and the delivery check valve will be open at this point. The cycle repeats when the low level gets reached. Innovative Enerpro Pvt. Ltd. is the leading Condensate Recovery System Manufacturers In India. Manufacturing state of the art equipment made from high-quality raw materials is our forte!

Make a call

+91 98 241 5754

Email us

info@ienerpro.com

Condensate Recovery System - We Are The Top Suppliers!

Innovative Enerpro Pvt. Ltd. has been in the business of manufacturing and supplying energy-saving products since 2010. We supply condensate recovery systems to various industries across the globe. Condensate recovery systems are an inclusive part of the machinery. Market demand for our product line is strong, as is the level of satisfaction of our customers. After some time, we delete the puncher ss float. We utilise a long-lasting float made of a specific substance. As a result, there will be little to no need for maintenance. For the majority of its lifespan, our system will continue to operate without interruptions. As a result, we are the leading Condensate Recovery System Suppliers.

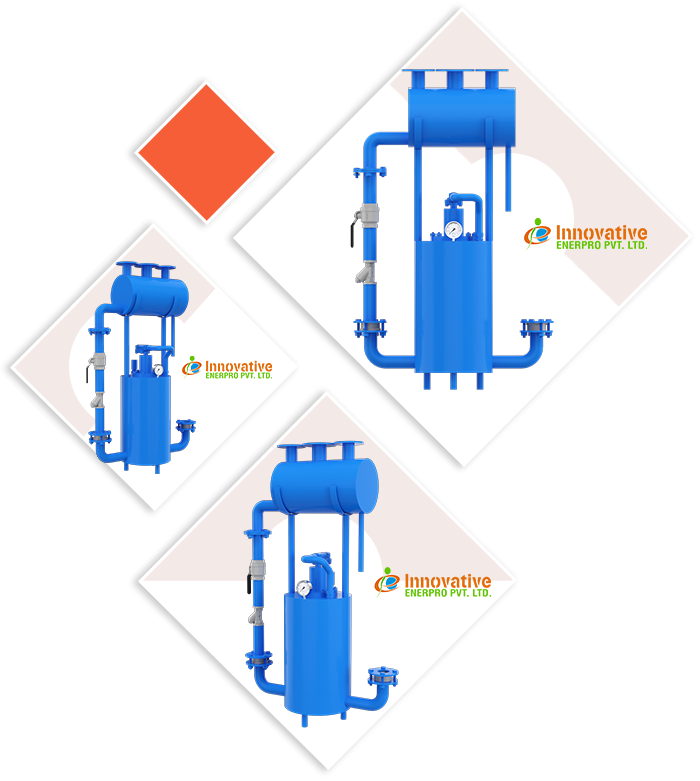

Product Gallery

Further Product Detail

- Textile

- Petro Chemical

- Pharmaceutical

- Processing unit

- Chemical Industry

- Paper and Sugar Mill

- Automobile Sector

The application area of these pumps is wide. They get employed in different machines for different industries. Such as –

Application In different Machines –

- Tracing Line

- Heat Exchanger

- Dryer

- Vessels

- Jacketing

- Oven

- Heating Tank

- It is environmentally friendly and preserves fuel up to 7 percent.

- Fewer Expenditures on Fuel

- A high temperature for the feed water to the boiler reduces the amount of dissolved oxygen, which in turn helps prevent corrosion.

- Total dissolved solids (TDS) in the boiler water feed get lowered thanks to this treatment.

- Reduces the need for make-up water, hence lowering the expenditures connected with it

- Maintenance is reduced since there are fewer moving components.

- We infuse SS304 material in our pumps to ensure product longevity.

- You may save up to 7% on your fuel use.

- Reduced ETP and RO treatment costs.

- We offer pumps in different capacities and sizes. The maximum capacity we provide in our pump is 6,000 kg/hr.