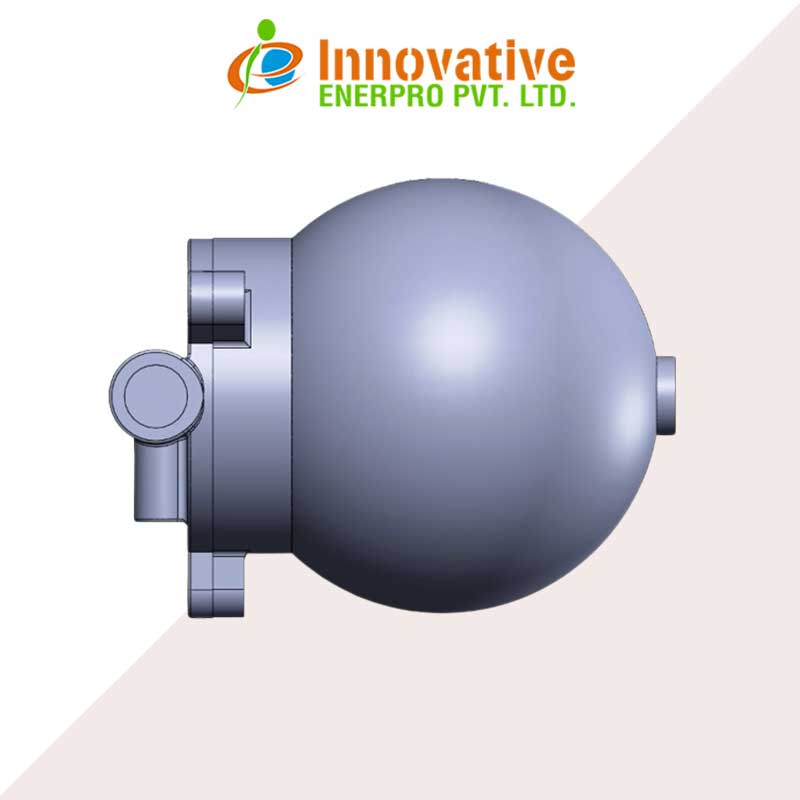

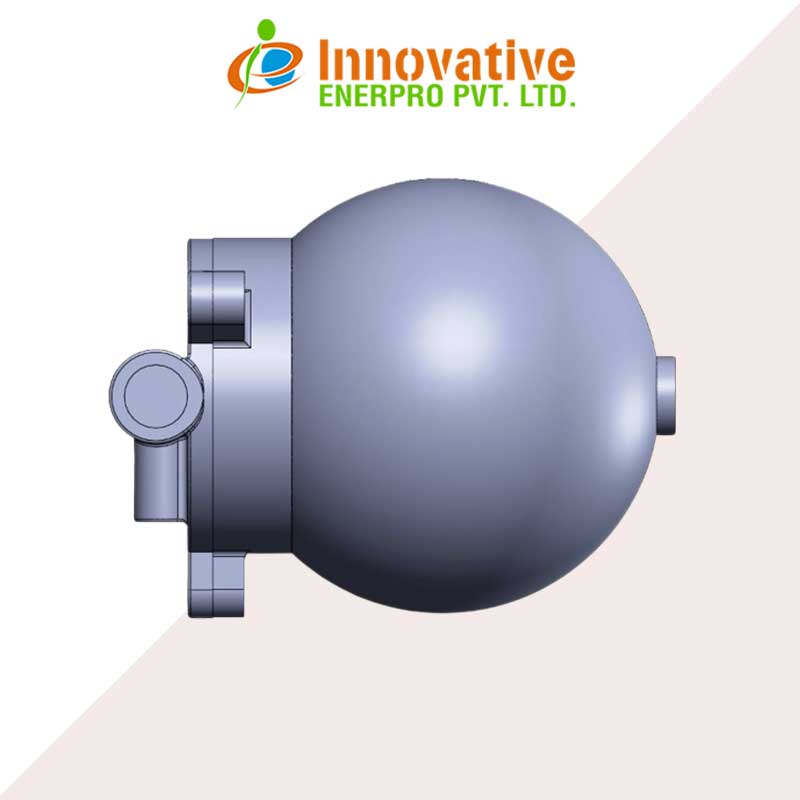

Float Trap - The Working Principle

Condensate level has a direct impact on the location of the float in float traps. The float reacts to condensate flow by opening and shutting the valve. The density concept is used in float or thermostatic traps. In the first stages of operation, a thermostatic vent in the trap’s top enables air to flow freely, and it shuts when the trap reaches saturation temperature. To open a discharge valve, a float chamber is filled with condensed water, which rises due to the presence of condensate. Depending on the amount of condensate, the seat may be opened or closed to adjust the amount of condensate burden. Innovative Enerpro Pvt. Ltd. is the top Float Trap Manufacturers In India. We manufacture our float traps under this principle only.

Make a call

+91 98 241 5754

Email us

info@ienerpro.com

Float Trap - We Supply The High-Quality Traps!

There is water beneath the discharge valve. To avoid the loss of live steam, a seal of water is formed. Venting of air and non-condensable gases is also prevented as a result of this. A large reduction in temperature is caused by the buildup of air and other non-condensable gases. These gases are expelled by the trap’s thermostatic valve. Innovative Enerpro Pvt. Ltd. has been in the business of supplying energy-saving products for over a decade now and we closely follow industry regulations. Our products are our trademark making us the leading Float Trap Suppliers in local and global markets.

Product Gallery

Further Product Detail

- Drains condensate completely at saturation temperature.

- Constant discharge at condensing load gets adjusted to meet low or heavy loads.

- During initiation, a separate thermostatic vent provides the air venting.

- Reduced warm-up time and improved heat transmission get achieved by using air vents.

- Modulating ports offers longevity.

- Repairing or replacing internal components does not require dismantling or disrupting the plumbing.

- Sterilizers

- Heating Coils

- Evaporators

- Tracer Lines

- Radiators

- Converters

- Unit Heaters

- Stainless steel modules get simply changed without causing any damage to the pipe system.

- The small size decreases the amount of space needed for installation.

- A cost-effective installation