Steam Powered Pump - A One In All Solution!

Since the year 2010, Innovative Enerpro Pvt. Ltd. has been manufacturing steam-powered pumps. These pumps have their uses in petrochemical plants and refineries for a variety of process applications, including boiler feed operations, low pump-out services, and others. Every one of the pumps that get powered by steam is a reciprocating, horizontal bidirectional, double-acting pump. In these pumps, the energy is transferred directly to the liquid terminal because the motive fluid generates an impact on the piston. Steam is often used as the motive fluid, although other options include air and gas. We are the leading Steam Powered Pump Manufacturers In India. Our in house team of experts make us bag happy clients worldwide.

Make a call

+91 98 241 5754

Email us

info@ienerpro.com

Steam Powered Pump - The Working Principle

The steam terminal is primarily a reciprocating two-cylinder steam engine that is an essential part of the machine. Each cylinder has a steam piston linked to a slide valve by a rod and levers. The valves get moved in either direction. The sliding valve is responsible for controlling both the input and output of the steam end. The steam enters the steam cylinder via the slide valve on one side, and this causes the piston to move toward the other side of the steam cylinder. Innovative Enerpro Pvt. Ltd. is the leading Steam Powered Pump Suppliers. If you wish to customise your products as per your application requirements, we can do that for you as well. Over the years, we have followed a client-first approach to authenticate our products and services.

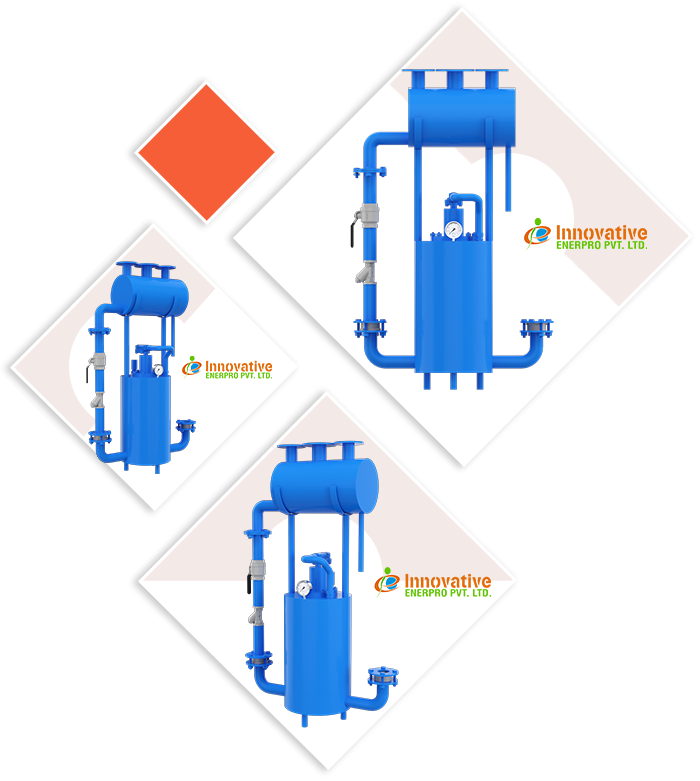

Product Gallery

Further Product Detail

- Petrochemical plants

- Oil Refineries

- Industries dealing in hazardous material handling

- At the equipment level, there is a recovery rate of 100 per cent for both the flash steam and the condensate.

- Works at a higher temperature for the recovery of condensate.

- It recovers the flash steam in its entirety

- Requires a high temperature of the supply water.

- The boiler blowdown is low.

- It saves 7-10% on fuel consumption

- These steam direct-acting pumps are incredibly versatile.

- A steam supply regulating valve operated manually or mechanically, can limit or increase the pump’s speed and, as a result, it’s capacity.

- Due to the smoothness of the valves, the maximum speed is largely restricted.

- The pump can function at wide temperature ranges i.e, from zero to a maximum given temperature.